Tooling & Fixture Design

Automate the entire tool development process including part design, tool assembly layout, and detailed tooling design and validation using advanced NX functionality. With step-by-step guidance and associativity to part designs, you can work with even the most challenging tooling and fixture designs

Advanced features to improve productivity

- Electrode Design

- Fixture Design

- Mold Design

- Progressive Die Design

- Stamping Die Design

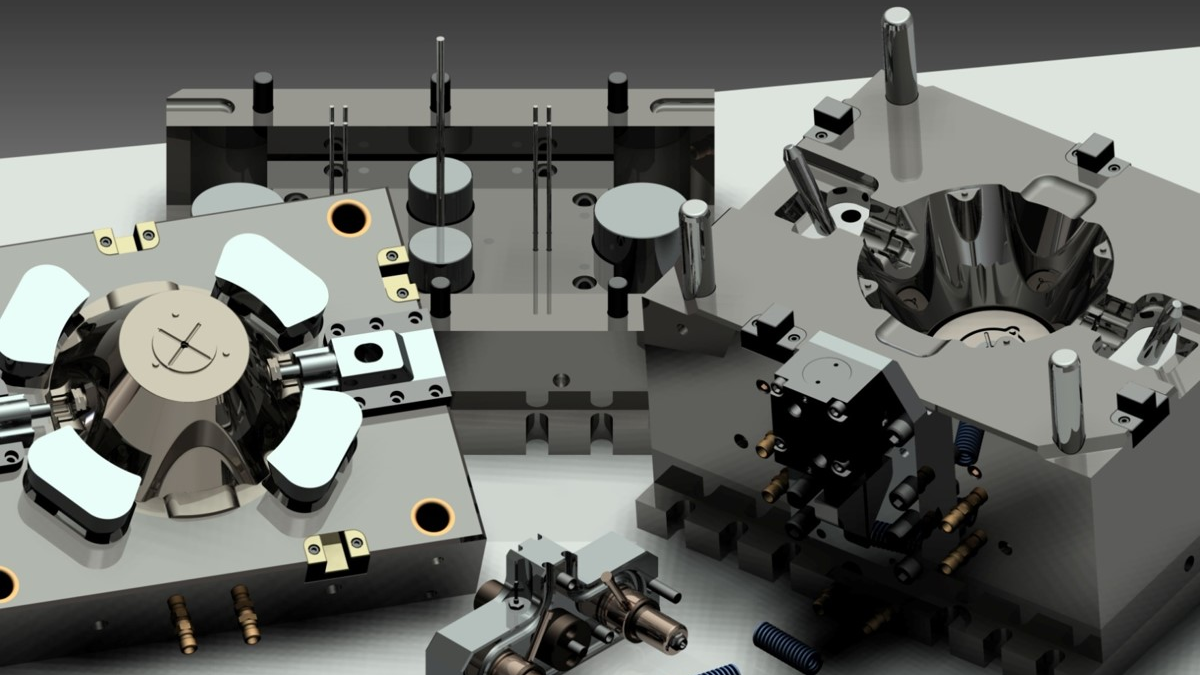

Electrode Design

- The electrode design software application in NX streamlines electrode modeling and design for any tool project that requires electrical discharge machining (EDM).

- NX electrode design software provides a time-saving, step-by-step solution that automates the entire EDM process from design through production. It can help you manage even the most complex and challenging electrodes.

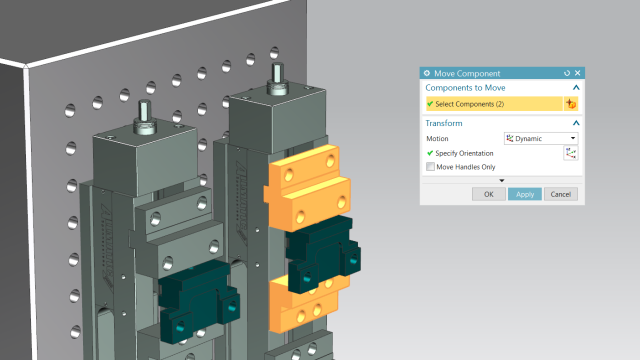

Fixture Design

Utilize powerful modeling and assembly tools to accelerate design of jigs and fixtures that are fully associative to the 3D part model.

You can easily position and mate fixture components with the NX assembly capabilities, and then automatically create drawings and documentation for the fixture and its components. NX also allows you to simulate the kinematics of fixtures, such as opened and closed positions, and check for strength and distortion.

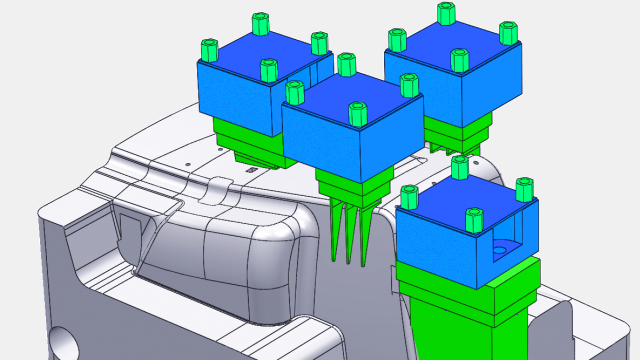

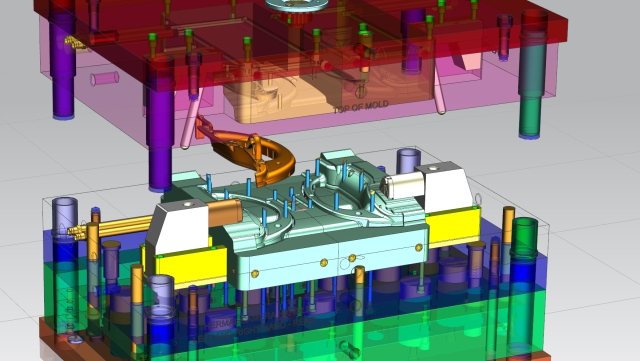

Mold Design

- NX Mold Design automates and streamlines the entire mold development process including part design, tool design and motion validation. You can ensure fast response to design changes and high-quality molds.

- Accelerate the design of the most challenging molds using advanced functionality, step-by-step guidance and associativity with part model to ensure fast response to design changes and quality molds.

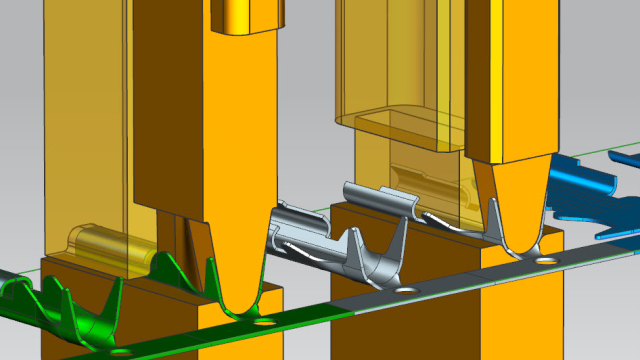

Progressive Die Design

- Our solution guides you through all of the stages required to design a progressive die, automating the most tedious tasks and streamlining complex processes. Our software for progressive die design is a comprehensive solution for both straight break and freeform sheet metal parts. You can design the complete die structure with associativity to the part design at every stage.

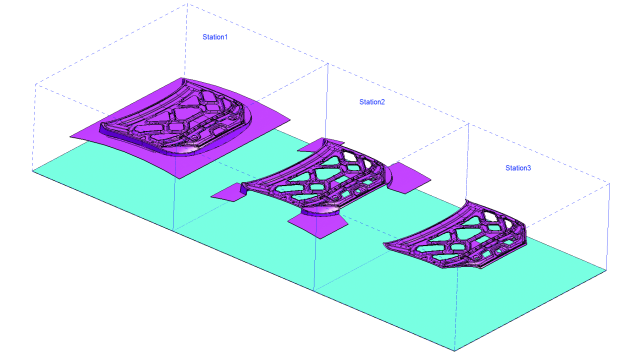

Stamping Die Design

- Advanced capabilities in our solution for designing automotive stamping dies include formability analysis, die planning, die face design, detailed die structure design, and die validation.

- Our stamping die solution guides you in defining the process used to manufacture complex stamped sheet metal parts, producing a representation of the press line and modeling the shape of the sheet metal as it leaves each press.